About fifteen consultants from ALTEN’s Innovation Department are working on two automotive research projects to promote sustainable innovation.

The first consists of exploring solutions for injecting water into the intake circuit or the cylinders to improve engine heat and more finely tune the combustion temperature. Our goal? Limit pollutants further while improving performance.

The second project focuses on the active aerodynamics and cooling systems applied to electric vehicles, which could optimise charging time, driving range and safety.

#1. “Liquid boost” :

a well hydrated car to stride ahead while polluting less!

This project originated at ALTEN’s Innovation Department based on an existing solution developed by a car industry supplier: injecting water into the engine to improve its heat management through induced cooling, guaranteeing better fill-ups and enhanced performance. Until then, this system had mainly been used in sports cars to fully optimise their engine power.

ALTEN’s Innovation Department wanted to use this technology to obtain the benefits of water injection, namely engine depollution, but with a use case applied to “everyday” cars, with the goal of perfecting it so that it would lead to lower consumption.

This technology responds to the CAFE standard, which requires manufacturers to limit carbon emissions to an average of less than 95 g/km based on data from all the vehicles sold over a year. Although the two major solutions to meet these environmental regulations lie in hybridisation and electrification, they will not be completely developed before 2035. Until then, initiatives must be taken so that internal combustion cars can get as close as they can to the requirements.

With the Liquid Boost project, ALTEN’s Innovation Department teams saw an opportunity to fine-tune the combustion temperature by capturing water from the exhaust gases and injecting it into the intake circuit or the cylinders.

There are two objectives to this:

- to improve the combustion engine’s efficiency and performance through cooling, as already permitted by ALTEN’s Innovation Department “model” technology,

- to reduce nitrogen oxide (NOx) emissions, since water has a beneficial impact on these pollutants and may even lessen the vehicle’s overall energy consumption.

This “two-pronged” technology, pushed to its limits by ALTEN’s Innovation Department, gives manufacturers better control over their pollutants and offers higher-performance engines.

Meanwhile, the ALTEN employees involved in this project are working to assess the technological potential of water injection and the water recovery system before launching further developments.

« Based on an existing technology, which has a very small window of opportunity to make an impact on reducing pollution, ALTEN’s Innovation Department will adapt how it works to make it just as beneficial to a simple internal combustion car as for a hybrid vehicle. »

Rémi BAYET – Specialist Consultant in Internal Combustion Engines

#2. Active aerodynamics and cooling:

a safer electric vehicle with a better driving range

While electric vehicles have a similar basic approach, they differ from combustion models in their practical requirements.

To understand the challenges of this project, it is important to remember how it originated », says Kévin BEHESHTI. Historically, electric vehicles are based on internal combustion vehicles. This means that, by convention, we have not necessarily imagined thinking differently about their structure, assuming that an electric vehicle has the same components as an internal combustion vehicle that are positioned in roughly the same places.

But these are precisely the main challenges for electric vehicles: they need to charge as quickly as possible and go as far as they can. For another example, a petrol vehicle will tend to heat up when fully loaded or at a stable speed, such as on the motorway at 130 km/h uphill, while an electric vehicle reaches its peak temperature when stationary. This observation led to the idea to make changes to electric vehicles’ architecture and optimise these parameters », the innovation leader said.

The architecture that inspired ALTEN’s Innovation Department teams has already proven itself in competition, with vehicles such as the Brabham BT46 and the Chaparral 2J. What makes them unique? It works like a vacuum that sucks up the road in its centre for better grip. The benefits that ALTEN’s Innovation Department expected from this technology lied in the parallel between how it works and the location of the battery on an electric vehicle: in the lower centre. This is a chance to benefit from airflow with an aerodynamic effect that could improve electric vehicle batteries’ heat management by cooling them, especially during fast charging while at a stop.

Another perceived advantage of this architecture is that it optimises electric vehicles’ safety. Since they are heavier than internal combustion vehicles, their tyres are subject to greater weight stress. This constraint can be cancelled by adding aerodynamic support: since the vehicle has mass, it will have inertia in bends; on the other hand, an aerodynamic support, in other words virtual mass on the tyres, presses more intensely on them, allowing more energy to pass without adding inertia. This allows heavier vehicles to turn just as well as lighter ones. And better turning allows for better braking control and, therefore, safer handling.

Once ALTEN’s Innovation Department teams had reached the end of this complex reasoning, basic and particularly critical issues for electric vehicles stood out.

Especially given that their numbers are expected to increase dramatically and that charging infrastructures will not be able to keep pace if each electric vehicle takes 30 minutes to fully charge.

Overhauling their architecture will:

1

use the flow of air taken in from the road to cool the battery, speeding up its charging time and power

2

extend driving range by a few kilometres thanks to better aerodynamics

3

improve the vehicle’s safety through aerodynamic support (the “vacuum” effect), allowing it to turn corners better and offering it improved stability

These also give car manufacturers hope of being able to overcome the constraint of having to install a big battery in the electric vehicle.

This advance would make it lighter, more affordable, and more environmentally friendly. This is especially relevant given that the battery is the most difficult vehicle component to industrialise and recycle.

This innovative project gives hope of making electric vehicles as easy to use as an internal combustion engine vehicle, especially in terms of charging time and driving range, which would be an attractive sales argument, encouraging an influx of buyers for less polluting vehicles.

To date, ALTEN’s Innovation Department has succeeded in setting up the first complete aerodynamic simulations and aims to integrate thermal coupling into them.

Teams with advanced skills and methodologies:

behind the scenes of innovation

Every day when working towards the major milestones of these two research projects, ALTEN’s Innovation Department teams use simulation tools equivalent to Matlab Simulink and GT-Power.

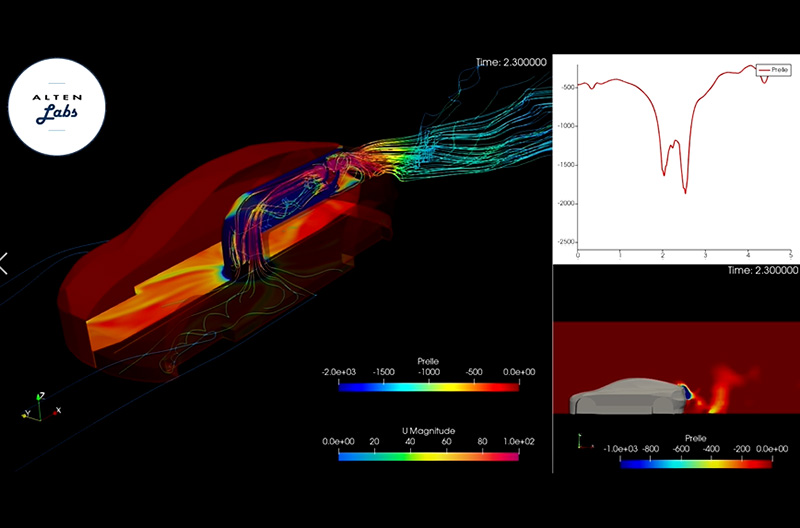

The more visual tools use Computer Aided Design (CAD) and Computational Fluid Dynamics (CFD) principles.

The latter helps us to produce digital wind tunnels both for air-type fluids as well as liquid-type fluids, for example to observe how the engine behaves when water is going to be injected into the engine air circuit.

More specifically on the subject of active aerodynamics/cooling, external aerodynamics will be carried out with this fan which will be integrated into the vehicle and combined with aerothermal aspects, as illustrated below.

Mastery of CFD modelling as well as skills in motorisation, heat (relevant to internal combustion as well as electric vehicles, applied to improving battery charging) and design allow ALTEN consultants to meet a multitude of customer needs, which are of great interest to researchers and manufacturers.

As part of the liquid boost project, the ALTEN Group benefits from a transversal position on the combustion propulsion train of a vehicle, which allows it to communicate and liaise with a wide range of the players in the product, such as the manufacturers of the engine, injectors, reservoirs, lines, and fluids to be injected into the system.

Beyond the technical skills that ALTEN’s Innovation Department teams have developed, its members identify most with their power for ideation.

« Our objective is to put our inventiveness and our ability to innovate at the service of research that works by trial and error, that tests and succeeds. »

The purpose of a research topic at ALTEN’s Innovation Department is not necessarily to develop a product: we conceive of innovative ideas, and we cultivate our ability to ask ourselves the right questions and to create hypotheses that we will then explore.

« We offer our customers a state of mind and our skills to develop solutions and tools hand in hand with them », says Kévin BEHESHTI.

This methodology justifies the changes to, even total 360° turns of the research projects discussed above. For example, when it was envisaged in late 2019, the Liquid Boost project was intended to improve vehicles’ performance in kilowatts and, thus, the power of the drive trains. But, after a few ideations, the research interest switched to the subject’s environmental concerns.

This reorientation was made possible by the teams’ agility as well as the diversity of their experience, particularly with manufacturers. « It’s a real asset to never stop learning and sharing », concludes Rémi BAYET.